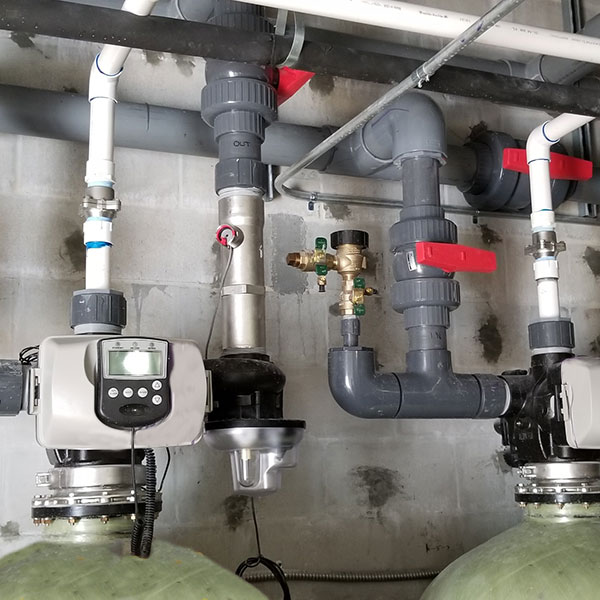

How Water Commercial Water Softeners Work

The process whereby hardness minerals are removed is described below:

- Water flows through the resin bed.

- As this occurs, hardness minerals (Calcium & Magnesium) are attracted to the resin and are removed from the water.

- Eventually, the resin reaches its capacity and the resin must be cleaned. (This process is called “regeneration”.)

- The control valve initiates the “cleaning process”, based on gallons used (not time) to limit salt consumption.

- During the cleaning process, brine water flows through the resin bed, removing the water hardness minerals because they are attached to the sodium in the brine water.

- Finally, the resin is rinsed so no salt gets into the water entering your facility.

Cycles

Regeneration cycles are described below:

Backwash

This is an upward flow to remove any particles which have accumulated in the softener tank and to refresh the resin bed.

Brine draw

This important step is when brine water flows through the resin to remove the hardness minerals. During this cycle, hardness minerals become unattached from the resin and are attracted to the sodium, contained in the brine water.

2nd backwash

During this up-flow cycle, salt and hardness minerals are rinsed off the ion exchange resin.

Rinse (downflow)

This is an additional cycle to make sure the salt is thoroughly removed from the resin.

Refill

During the refill cycle, water is added to the brine tank so there will be a sufficient amount of brine water for the next regeneration cycle.

Service

This is when water flows through the softener to provide soft, conditioned water..